一,summary:

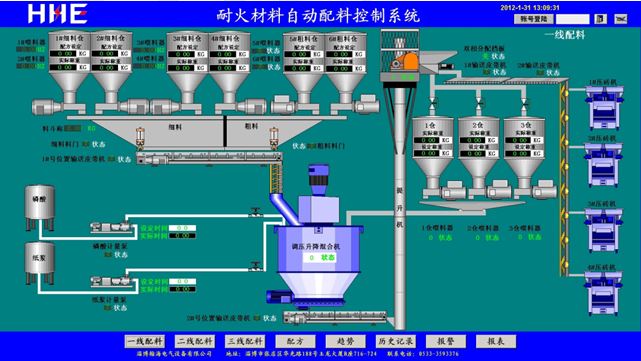

HHE-ABS(Automatic batching system)The automatic batching control system is a high-tech intelligent batching control system independently developed and designed by our company. The control system has powerful management functions, easy operation, and precise control. The software design adopts standardized interfaces and modular structure design, making it easier to expand the system, increase functions, and expand business.

二、Technical performance and characteristics of the ingredient system

1、Implement manual operation and automatic control of ingredient functions;

2、Beautiful and practical dynamic simulation of the production process, capable of displaying real-time working status and the target weight, actual weight, and error value of each material; Implement order issuance, execution, and raw material demand statistics, as well as add and delete raw materials

3、Pre set storage formula, which can be called, modified, deleted, and queried at any time;

4、The historical records of each batch of ingredient data are saved, and the production and material consumption can be reported, queried, and printed at any time on a shift, daily, monthly, and annual basis;

5、During the ingredient preparation process, there is an automatic shortage alarm and the warehouse number containing the same material can be manually replaced online;

6、It has functions such as operator permission management, on-site management, and networked remote services;

7、Adopting imported industrial computer (IPC) as the upper computer monitoring system, equipped with friendly interface monitoring software and reliable database, to ensure the stability, reliability, and long-term performance of the system.

8、The entire system is in human-machine dialogue mode, which is easy to operate and maintain;

9、Remote management can be achieved, and the computers in the control room can be connected to the computers of the management team to view production status and reports in real time.

10、By using a frequency converter to control the feeding process, the accuracy of the ingredients can be improved, thereby enhancing the quality and stability of the product.

三.Main application industries:

It can be widely used in industrial fields such as feed, refractory materials, concrete ingredients, carbon, glass, ceramics, food, metallurgy, chemical industry, etc. It is suitable for continuous measurement of materials and ingredient operations in the production process. The use of this system can effectively improve ingredient accuracy, enhance product quality, greatly reduce labor intensity for workers, increase work efficiency, and improve the working environment.

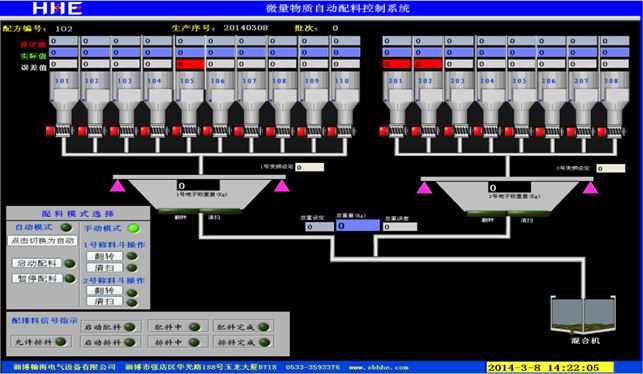

Typical application cases of high-precision micro material automatic batching:

一、Application in the feed industry

Realize high-precision micro weighing, with a total control accuracy of up to 0.03%

二、Application in the refractory material industry