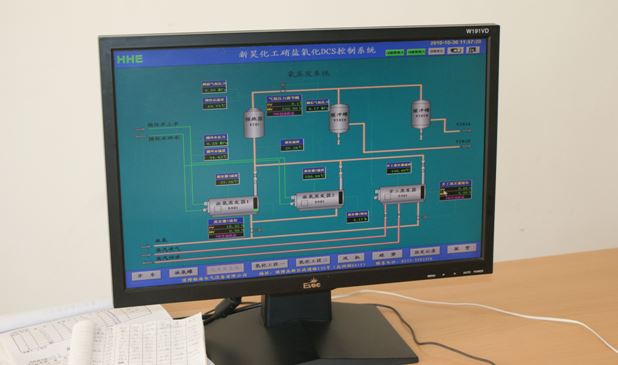

DCS control system for nitrate oxidation section

The system reflects the operating status of the entire system through an intuitive production process interface, provides timely feedback on system information, and can control the operation of the entire system through operations on the computer interface.

1、The lower level system adopts imported Siemens modular design, with stable and reliable performance, and easy maintenance, upgrading, and expansion.

2、The functional coverage of nitrate safety production quality control includes signal acquisition and processing systems, signal control systems, and safety warning and alarm systems.、

3、There are two ways to control the system: remote control and local control mode. This multiple insurance ensures the stability of the system.

4、The controlled objects within the system functional area maintain appropriate independence during hardware configuration to ensure that a single control station failure does not affect the operation of the system. The system is easy to configure, easy to use, easy to expand, increases system flexibility, reduces the data communication load of the process control bus, and ensures a utilization rate of at least 99.9% for the entire system.

5.Regular records: including shift handover records, daily reports, and monthly reports. The system will record all operational items carried out by operators in the control room and the precise time of each operation. By accurately recording the operational behavior of operators, it can facilitate the analysis of their operational intentions and the causes of system accidents.