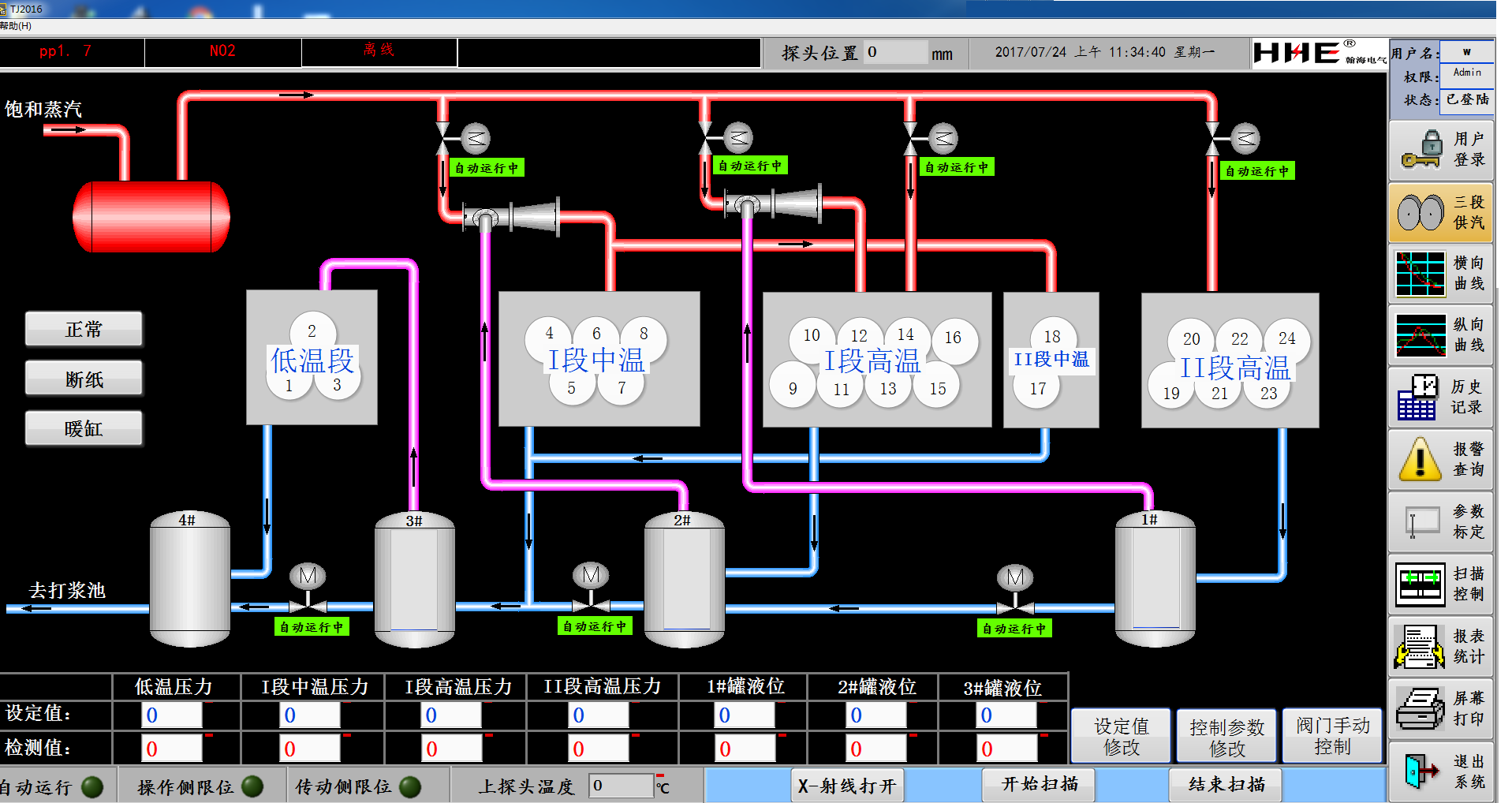

Three stage steam supply electrical control system

System ID: HHE-TSSCS

System features:

Due to the use of a heat pump for steam supply, there is no correlation between secondary steam in each section, and the steam supply is relatively independent. The condensed water discharged from a certain dryer group enters the flash tank, and due to pressure changes, the condensed water naturally flashes out secondary steam. This part of the secondary steam is pressurized by the heat pump injection and sent back to this section for reuse. At the same time, due to the injection suction effect of the heat pump, the pressure in the flash tank will further decrease, and more secondary steam will be flashed. When the heat pump system is in its optimal state, about 18% of the 25% of the total heat energy consumed from the dryer will be sent back to the dryer for reuse. The remaining low-pressure low-temperature condensate water that has undergone multiple flash evaporation processes only has about 7% of its thermal energy sent away through the terminal condensate pump. The heat pump system commonly referred to as saving at least 15% energy is based on this theoretical analysis.

System composition:

This system consists of hardware components such as an injection heat pump, orifice plate steam trap, flash tank, condensate tank, electric valve, pressure transmitter, differential pressure controller, liquid level transmitter, Siemens S7 series PLC main control unit, color display, industrial computer, standard on-site control cabinet, and AC stabilized power supply.