20 ton coal powder boiler monitoring system

In order to ensure the safe and normal operation of the coal powder boiler and take into account the characteristics of the system, under the premise of ensuring safety, reliability, economy, and rationality, the internationally advanced Siemens PLC is selected as the core control unit. This series of PLC control systems has powerful functions and flexible expansion configurations.

All controlled and monitored variables of the system, including digital and analog signals, are comprehensively controlled by PLC to achieve monitoring and adjustment control of the main parameters during the start-up, shutdown, and combustion process of the coal powder boiler.

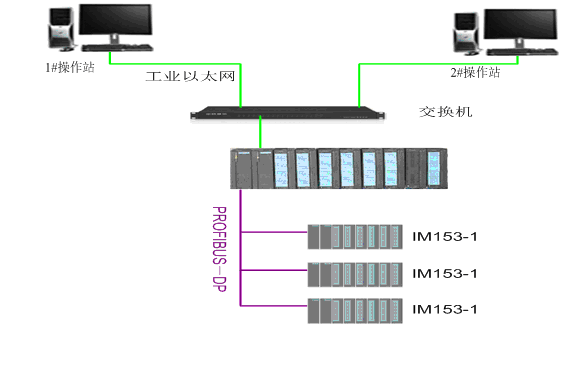

Distributed I/O stations can be added as needed, which can be placed next to centrally installed instrument equipment on site to save investment in cable installation and manual labor.

The software system has a friendly human-machine interface and powerful communication functions. It can easily complete various complex control algorithms to meet on-site needs.

The basic idea of this scheme design is to control decentralization, centralized operation, hierarchical management, flexible configuration, and convenient configuration.

一、Basic architecture of the system

Figure 1 System Architecture Diagram

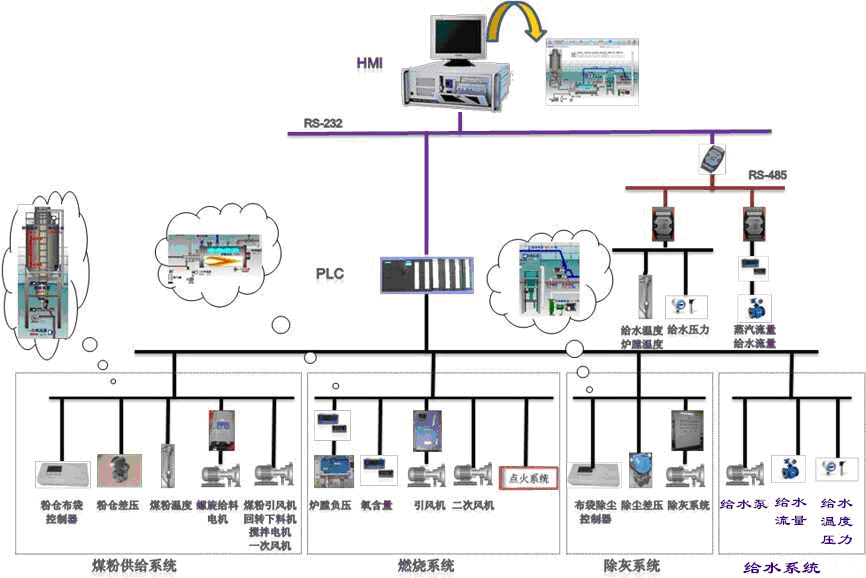

Figure 2 System Application Extension and Supplement

As shown in the figure, the system uses industrial computers to implement upper computer monitoring, and the control methods are divided into three types: centralized control automatic, centralized control manual, and local control. When the boiler is running normally, the centralized control automatic mode is used, and the equipment is automatically controlled and protected by the central console in the order and process required by the process; When the centralized control is manual, various devices can be operated from the central console, with interlocking and linkage relationships; When operating locally, the equipment can be started and stopped on site.

The upper monitoring system is equipped with two high-performance industrial computers, which serve as backups for each other. Any computer problem will not affect operation.

The control layer uses Siemens series PLC, which has powerful control functions, is safe and reliable, and can flexibly match expansion modules to fully meet control needs.

The control system can monitor and operate all subsystems of the coal powder boiler, including the supply system, combustion system, ash removal system, and water supply system, as well as dust removal, desulfurization, and denitrification, to meet the needs of centralized monitoring.

二、 Characteristics of control system

2.1High reliability

u High reliability I/O modules: point-to-point isolation, point-to-point mutual isolation, point-to-point power distribution, online point-to-point replacement, can meet the requirements of high reliability and high safety fields such as nuclear power and emergency shutdown.

u Intelligent design of components: I/O modules, I/O modules, control modules, and communication modules are all equipped with microprocessors or multiprocessors, supporting module self diagnosis, fault isolation, and online plugging and unplugging.

u Intelligent conditioning technology:

Supports analog universal input, software configuration type, full range high-precision, lossless digital transmission, self diagnosis and self correction, calibration free and maintenance free.

u Electromagnetic compatibility design:

Ø Anti transient fast group pulse interference, signal end 1000V, power supply end 2000V;

Ø RF interference suppression, transmission power 5W/0.5m;

Ø Low power design, no need for forced heat dissipation.

u Operational safety design:

Ø Real time data power-off maintenance, redundancy verification, fast recovery, ensuring system information security.

2.2System Open

Ø The system has rich communication interfaces, such as industrial Ethernet and standard OPC specifications, to meet different on-site needs.

Ø The data exchange interface, driver program interface, etc. fully open the system to users, allowing them to expand its functions and unleash their individuality.

Ø The WEB publishing function allows users to remotely access and facilitate factory management.

Ø Configuration languages include functional block diagrams, ladder diagrams, SFC, structured text, etc.

Ø Based on modular system hardware, open software platform, and specialized application software, flexible integration can be achieved, and horizontal or vertical expansion can be carried out as needed.

2.3 Powerful functionality

Ø Support integrated development environment and offline/online programming.

Ø Support massive historical data recording, trend charts, statistical tables, and data analysis.

Ø 支持控制策略的在线组态与在线调试。

2.4 Easy to operate

Ø Simple boiler start stop: The boiler system can be started and stopped immediately, cutting off the ignition source and entering normal operation within 30 seconds; Cutting off the coal powder supply can achieve shutdown.

Ø High level of measurement and control: automatic monitoring and adjustment of operating parameters throughout the process to keep the system in optimal operating condition; At the same time, it reduces the impact of labor intensity and human factors on boiler operation.

Ø Efficient and energy-saving: Optimize control technology to ensure sufficient combustion of coal powder, reduce excess air coefficient, and improve system thermal efficiency; Equipping high-power electrical equipment with frequency converters has a significant energy-saving effect.

2.5 Easy to maintain

Ø IO module configuration combination industrial wiring terminal group, standardized interconnection inside the cabinet, convenient for users to use and maintain;

Ø Support module, module, network self diagnosis, module can be plugged and unplugged with power, and repaired online.

Ø Module intelligence, multifunctionality, limited types, easy maintenance, and reduced spare parts.

Ø The analog input type and digital input/output mode can be set by software, making it easy to select and modify.

On site display